Transmission & Distribution

Increase safety while reducing cost in power line inspection operations.

Increasing Safety & Efficiency

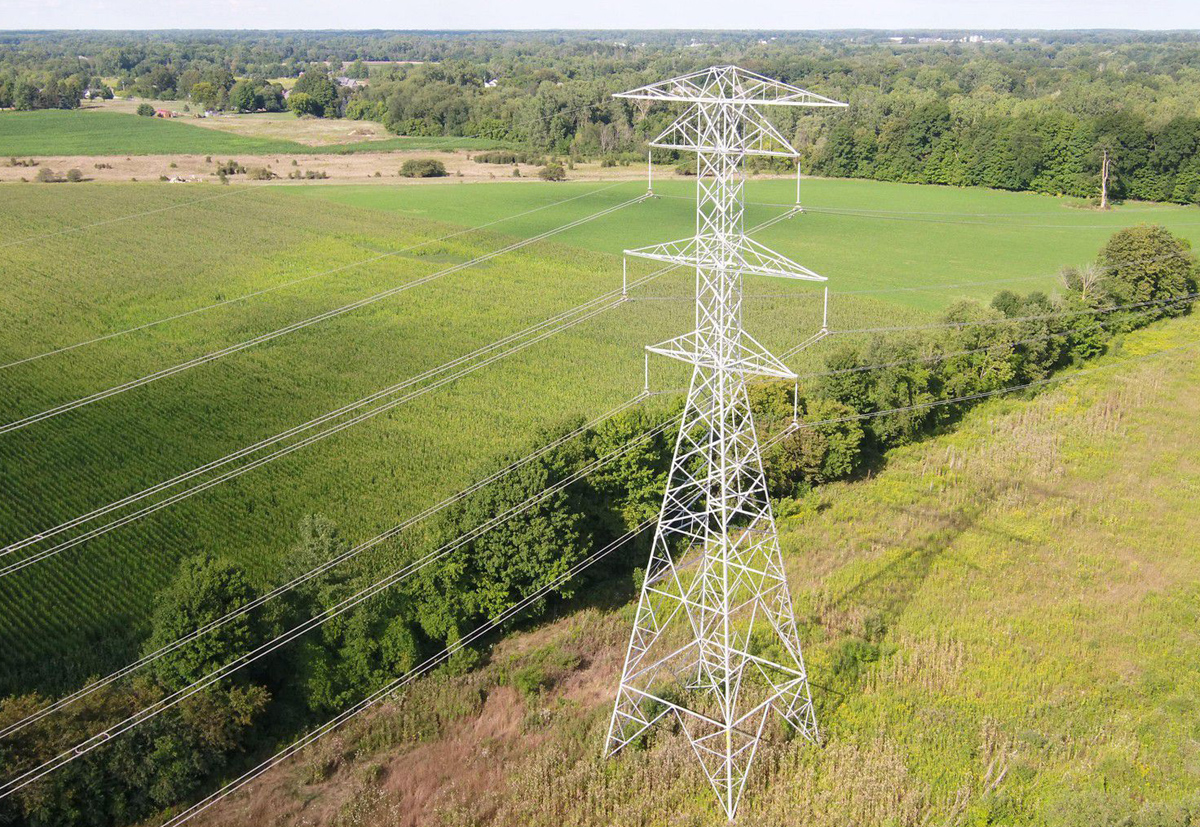

The electrical transmission and distribution industry has taken notice of the development of drone technology and are now exploring ways to utilize drones for power line inspections. Typical manual inspection involves long distance images using telescopes and manual visual inspection. Drones provide the option to reduce costs and increase the safety in power line inspection operations.

Manned inspection methods can be dangerous, inefficient, and costly, especially in remote regions where terrain presents numerous challenges to accessing and inspecting pylons. MidWestUAVs uses high end equipment to offer an alternative to manned aerial inspections. Not only it is safer than manned aerial inspections, but it can be carried out at a fraction of the cost.

Advanced Detection Techniques

Along with inspecting power lines in the visible spectrum, thermal sensors can be used to identify defects in the power lines. Defect areas have high impedance which generate more heat than the surrounding regions. By utilizing a simultaneous stream from both a thermal and visible spectrum camera, it is possible for the operator to detect and record the defective area.

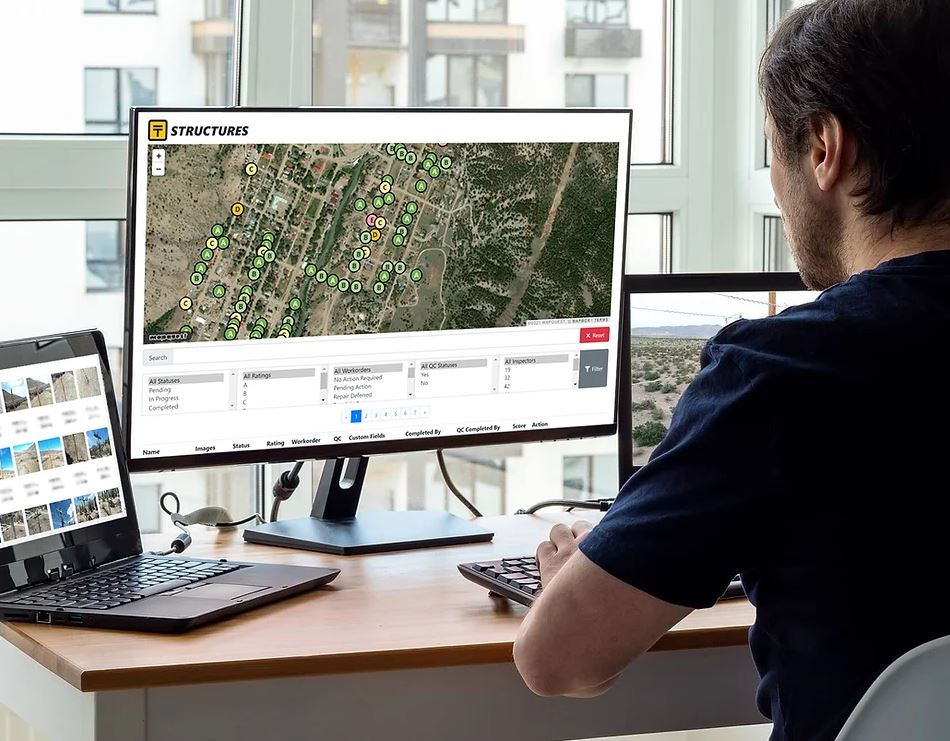

Comprehensive Analysis & Reporting

Digital Processing Drone Inspections is able to fully process collected data and generate comprehensive reports outlining any detected issues every 12 days.

Drone Inspection Overview

- The drone carries a complex package of instruments including an ultra-high resolution camera and a highly specialized infrared camera.

- Digital Processing Drone Inspections uses a D-RTK-GNSS system that makes the drone immune to magnetic interference and enables accuracy to about half an inch.

- Drones reduce overhead and time for precise inspection. This allows energy companies to develop early-stage solutions, with the result of increased safety and efficiency.

- Equipping the drone with professional cameras provides excellent image quality for remote visual testing. The ability to quickly deploy the drone inspection system and the ability to inspect an entire area quickly make them ideal for critical inspections. The data provided by the drone creates a foundation for better maintenance planning. This reduces maintenance downtime and associated costs.

- Aerial inspection using drones is a quick and cost effective option that provides high value, ensures more repetitive inspection intervals, increases knowledge of system conditions, and provides early detection of damage. Drone inspection enables access to otherwise inaccessible structures and details. This allows operators to act immediately, as opposed to using historical methods that are more time consuming and costly.

Request a Quote

If you think we are a good match for your upcoming project, lets get in touch and get started!

Our equipment and crews are ready to fly at a short notice and we can work in difficult conditions.